A self loading concrete mixer is a multifunctional construction machine that integrates automatic loading, precise weighing, mixing, transportation, and discharging functions into one unit. It combines the capabilities of a loader, mixer, and transporter, eliminating the need for additional equipment such as a loader or batching plant, thus forming an independent and efficient small-scale concrete production system.

This type of mixer is suitable for various construction sites because it can operate in narrow or rugged terrains and requires only one person to operate. It revolutionizes the traditional mode of ready-mix concrete production and transportation by combining the functions of a "small mobile batching plant" and a "concrete mixer truck" into one machine.

Self Loading Concrete Mixer Truck Specifications

| Product Name | Production Capacity (m³/Drum) | Rated Power (kW) | Drum Capacity (L) | Max Speed (km/h) | Max Climbing Grade (°) | Drum Rotation | Fuel Tank (L) | Water Tank (L) |

| Self Loading Concrete Mixer 1.2 Cubic | 1.2 | 55 | 1700 | 30 | 30 | 270–360° | 63 | 400 |

| Self Loading Concrete Mixer 1.8 Cubic | 1.8 | 78 | 2740 | 30 | 30 | 270–360° | 63 | 400 |

| Self Loading Concrete Mixer 2.6 Cubic | 2.6 | 78 | 3000 | 30 | 30 | 270–360° | 75 | 500 |

| Self Loading Concrete Mixer 3.5 Cubic | 3.5 | 85 | 4740 | 30 | 30 | 270–360° | 75 | 620 |

| Self Loading Concrete Mixer 4.0 Cubic | 4 | 85 | 6000 | 35 | 45 | 270–360° | 230 | 660 |

| Self Loading Concrete Mixer 5.5 Cubic | 5.5 | 85 | 7800 | 42 | 45 | 270–360° | 180 | 860 |

| Self Loading Concrete Mixer 6.5 Cubic | 6.5 | 92 | 9000 | 40 | 45 | 270–360° | 370 | 1465 |

Haomei Machinery Self Loading Concrete Mixer Truck for Sale

-

Self Loading Concrete Mixer 1.2 Cubic

Self Loading Concrete Mixer 1.2 Cubic

-

Self Loading Concrete Mixer 1.8 Cubic

Self Loading Concrete Mixer 1.8 Cubic

-

Self Loading Concrete Mixer 2.6 Cubic

Self Loading Concrete Mixer 2.6 Cubic

-

Self Loading Concrete Mixer 3.5 Cubic

Self Loading Concrete Mixer 3.5 Cubic

-

Self Loading Concrete Mixer 4.0 Cubic

Self Loading Concrete Mixer 4.0 Cubic

-

Self Loading Concrete Mixer 5.5 Cubic

Self Loading Concrete Mixer 5.5 Cubic

-

Self Loading Concrete Mixer 6.5 Cubic

Self Loading Concrete Mixer 6.5 Cubic

As a global leading manufacturer of self loading concrete mixers, Haomei Machinery has exported its products to more than 150 countries and regions. With reliable quality and proven technology, our mixers are highly trusted by contractors, building material companies, and engineering project clients.

Our self loading concrete mixers integrate loading, weighing, mixing, transporting, and discharging into one unit. A single machine can complete the entire concrete production process, significantly reducing labor costs and time consumption. The equipment is equipped with a high-precision electronic weighing system, keeping the weighing error within ±2%, ensuring stable concrete proportions and higher discharge quality.

Latest Project Cases of Haomei Self-Loading Concrete Mixers

Philippines Road Construction Project

- Equipment: 3 units of self loading concrete mixers

- Capacity: 3 m³ per batch, about 12 m³/hour

- Drum rotation angle: 270 degrees

- Features: suitable for highway construction, fast unloading, labor-saving

Saudi Arabia Industrial Park Construction

- Equipment: 6 units of self loading concrete mixers

- Capacity: 5 m³ per batch, about 20 m³/hour

- Drum rotation angle: 270 degrees

- Features: suitable for large-scale industrial park projects, stable concrete supply, easy operation

Brazil Residential & Commercial Complex Project

- Equipment: 3 units of self loading concrete mixers

- Capacity: 3.5 m³ per batch, about 14 m³/hour

- Drum rotation angle: 270 degrees

- Application: ideal for mixed residential and commercial projects, flexible mobility, small footprint, quick discharge

Vietnam Residential Community Construction

- Equipment: 2 units of self loading concrete mixers

- Capacity: 2.5 m³ per batch, about 10 m³/hour

- Drum rotation angle: 270 degrees

- Application: suitable for small-scale residential projects, easy to maneuver, compact design, ideal for narrow construction sites

Egypt Port Expansion Project

- Equipment: 5 units of self loading concrete mixers

- Capacity: 6 m³ per batch, about 24 m³/hour

- Drum rotation angle: 270 degrees

- Features: suitable for large-volume concrete supply, reduces construction time, strong durability

Nigeria Municipal Road Construction

- Equipment: 4 units of self loading concrete mixers

- Capacity: 4.5 m³ per batch, about 18 m³/hour

- Drum rotation angle: 270 degrees

- Application: suitable for municipal road construction, fast on-site mixing, easy transportation

Features of Self Loading Concrete Mixer Truck

- Integrated operation: a single machine completes the entire process from raw materials to finished concrete.

- One-person operation: only one driver is required to complete all tasks.

- Strong mobility: compact design with a small turning radius, suitable for narrow sites and rugged terrain.

- Precise batching: equipped with an onboard weighing system and automatic water addition control to ensure stable concrete quality.

- Automatic loading: uses the built-in bucket to load raw materials such as sand, gravel, and cement into the mixing drum.

- On-site mixing: mixes the materials directly at the construction site to produce ready-mixed concrete.

- Flexible discharge: the mixing drum usually rotates up to 270 degrees, allowing the operator to pour concrete from multiple directions and from heights up to two meters.

- Maneuverability: designed for complex terrain, these mixers feature a four-wheel drive system and a smaller turning radius than traditional concrete mixer trucks, enabling access to hard-to-reach areas.

- On-demand concrete pouring: can precisely pour the required amount of concrete, minimizing waste.

- Operator control: all functions—from loading and mixing to discharging—can be controlled by a single operator, usually via joystick controls.

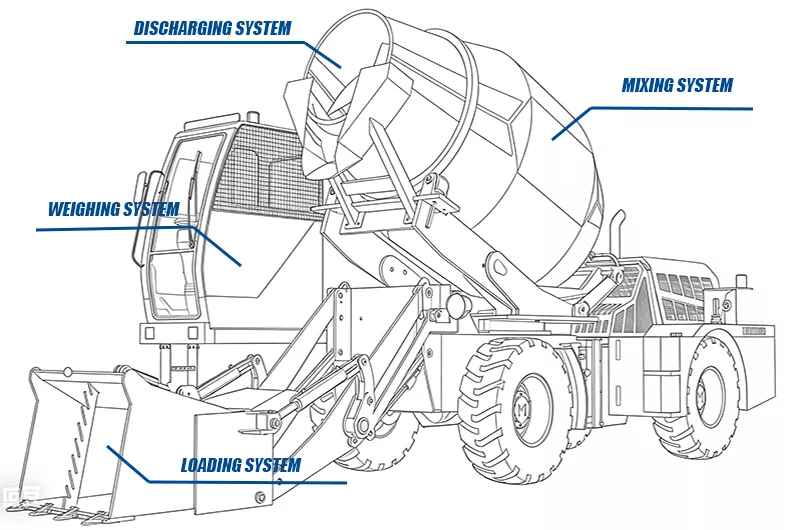

Components of Self Loading Concrete Mixer Truck

A typical self loading concrete mixer truck usually integrates the following systems:

- Chassis truck: provides power and mobility.

- Loading system: a hydraulic bucket located at the front or side of the vehicle, used for scooping aggregates.

- Aggregate hopper: receives aggregates from the bucket and includes a metering function.

- Cement silo/system: typically a sealed silo equipped with an arch-breaking device and a screw conveyor or pneumatic conveying system to store and measure cement.

- Water tank and metering system: stores and accurately measures the mixing water.

- Mixing drum: similar to that of traditional mixer trucks but often designed for higher mixing efficiency; located at the rear of the vehicle.

- Batching and control system: the core brain. Usually a computer control system with a touchscreen where the operator inputs the mix formula, and the system automatically controls the sequence and weight of each material to ensure concrete quality.

- Hydraulic and power system: provides power for all actions such as loading, conveying, and mixing.

-

Self-loading concrete mixer truck loading hopper

Self-loading concrete mixer truck loading hopper

-

Self-loading mixer truck double-blade mixing system

Self-loading mixer truck double-blade mixing system

-

Self-loading concrete mixer truck tires

Self-loading concrete mixer truck tires

-

Self-loading concrete mixer truck cab

Self-loading concrete mixer truck cab

-

Self-loading concrete mixer truck motor

Self-loading concrete mixer truck motor

-

Self-loading concrete mixer truck water pump

Self-loading concrete mixer truck water pump

Advantages of Self Loading Concrete Mixer Truck

- Improved efficiency: replaces multiple machines with one vehicle, reducing labor and time.

- Cost saving: requires only one operator, eliminating the need for separate loading and transport vehicles.

- Reduced waste: can accurately mix and distribute concrete as needed.

- Versatility: suitable for a wide range of construction projects and performs well on complex terrains.

Exceptional flexibility and convenience:

- No need for a fixed batching plant: ideal for remote areas, small job sites, and scattered work points (such as rural roads and dispersed residential construction).

- On-demand production: can produce the required amount of concrete anytime and anywhere, avoiding waste or shortages caused by inaccurate estimations in traditional methods.

- Reduced intermediate steps: eliminates the cost and time of transporting concrete from a batching plant to the job site.

Lower overall costs:

- Saves the high investment required to build a fixed batching plant.

- More flexible raw material sourcing, allowing materials to be obtained locally.

- Reduces concrete waste and disposal.

Environmental protection:

- Integrated production and transportation reduce road pollution and carbon emissions caused by multiple vehicles.

- On-site control eliminates wastewater and residue issues caused by long-distance transportation.

Applications of Self Loading Concrete Mixer Truck

Self loading concrete mixer trucks are widely used across various construction fields due to their flexibility and efficiency.

- Infrastructure construction: roads, bridges, tunnels, and ports.

- Commercial and residential projects: houses, buildings, warehouses, parking lots, and residential communities.

- Remote and rugged terrain: mountainous and rural areas where fixed concrete batching plants are difficult to reach.

- Special fields: military engineering, emergency rescue, oil fields, mining areas, and other remote locations lacking urban infrastructure.

Haomei Self Loading Concrete Mixer in action for large-scale infrastructure construction projects, providing efficient concrete mixing and transport.

Haomei Self Loading Concrete Mixer delivering uniform concrete for road construction and paving projects.

Haomei Self Loading Concrete Mixer used for precast concrete production, ensuring precise batching and high-quality concrete output.

Self Loading Concrete Mixer Truck Working Process

- Preparation: drive the truck to the raw material storage area (one pile of sand, one pile of stone), connect to the bulk cement tanker or fill the onboard silo with cement, and fill the water tank.

- Batching: the operator inputs the required concrete volume and grade on the control panel.

- Loading and weighing: use the bucket to scoop sand and stone in sequence, pour them into the aggregate hopper and weigh automatically; the cement system and water system meter materials precisely according to the formula.

- Feeding and mixing: all raw materials are added to the mixing drum in sequence (usually most aggregates and water first, followed by cement and remaining materials). The drum rotates to mix while the vehicle is driving or parked.

- Transportation and discharge: after mixing is completed, fresh concrete is transported to the pouring point and discharged like a traditional mixer truck.

Differences Between Self Loading Concrete Mixer Truck and Traditional Mixer Truck

| Feature | Traditional Concrete Mixer Truck (Rear-Loading) | Self Loading Concrete Mixer Truck (Front-Loading) |

| Source of Materials | Loads pre-mixed or semi-mixed concrete from a fixed ready-mix concrete batching plant. | Directly loads sand, stone, cement, and water onsite or at a material yard. |

| Loading Method | Receives mixed concrete through the feeding port at the rear of the truck. | Typically uses a hydraulic loading bucket at the front or side to scoop aggregates; cement is conveyed by pneumatic or mechanical systems, and water comes from the onboard water tank. |

| Mixing Function | Main function is transportation and maintaining concrete consistency during transit, preventing solidification or segregation. | Core function is producing concrete from scratch — a complete mixing process. |

| Independence | Highly dependent on batching plants and supporting equipment. | Extremely independent — requires only a raw material storage area and water source. |

Haomei Machinery Self Loading Mixer, Powering Global Construction Projects

Haomei Machinery self loading concrete mixers have been exported to more than 150 countries and regions worldwide, including India, Indonesia, Vietnam, the Philippines, Kenya, Nigeria, South Africa, Saudi Arabia, the United States, Mexico, Malaysia, Russia, Uzbekistan, Kazakhstan, Myanmar, Thailand, Sri Lanka, Germany, the United Kingdom, Namibia, Somalia, the Dominican Republic, Australia, and more. With advantages such as efficient concrete mixing, reliable transportation, and integrated construction solutions, Haomei Machinery self loading concrete mixers play a significant role in global construction projects, infrastructure works, and various job sites, becoming an ideal choice for contractors.

-

Philippines 3.5 m³

Philippines 3.5 m³

-

Indonesia 5.5 m³

Indonesia 5.5 m³

-

Saudi Arabia 4.0 m³

Saudi Arabia 4.0 m³

-

United Arab Emirates 3.5 m³

United Arab Emirates 3.5 m³

-

Russia 3.5 m³

Russia 3.5 m³

-

Mexico 6.5 m³

Mexico 6.5 m³

-

Vietnam 3.5 m³

Vietnam 3.5 m³

-

Nigeria 5.5 m³

Nigeria 5.5 m³

-

Uzbekistan 2.6 m³

Uzbekistan 2.6 m³

Choose Self Loading Concrete Mixer Truck to Maximize Project Profit

Choosing a Self Loading Concrete Mixer Truck can help construction projects achieve maximum profitability. This equipment integrates loading, mixing, transportation, and discharging, greatly improving construction efficiency while saving labor and transportation costs. Precise metering and mixing reduce material waste, making it suitable for various job site environments, including narrow or remote construction locations. Meanwhile, the multi-functionality of a single machine reduces overall equipment investment, enhances project flexibility, and improves construction performance. Using a self loading concrete mixer truck not only optimizes the concrete transportation process but also significantly boosts project profit and schedule efficiency.

Self Loading Concrete Mixer Truck Maintenance & Service

Daily Inspection

- Check engine oil, radiator water level, and fuel condition.

- Check whether the hydraulic system is leaking and ensure hydraulic hose connections are secure.

- Inspect tire pressure and wear to ensure safe driving.

Drum & Mixing System Maintenance

- Clean the inside of the drum after each use to prevent concrete residue from hardening.

- Regularly check the wear of mixing blades and replace them if necessary.

- Lubricate the drum rotation bearings to ensure smooth mixing.

Hydraulic System & Transmission System Maintenance

- Replace hydraulic oil and filters regularly to prevent hydraulic failures.

- Check transmission chains or gears to ensure proper power transmission.

Electrical System & Safety Devices

Check whether all lights, alarms, and control buttons are functioning properly. Ensure the emergency stop device and safety valves are reliable.

Cleaning After Each Use

After each use, be sure to thoroughly clean the mixing drum of the self-loading concrete mixer to prevent concrete residue buildup. This helps avoid clogging and ensures smooth mixer operation.

Inspect and Replace Worn Parts

Regularly inspect parts such as blades, bearings, and seals for signs of wear. Replace any damaged or worn components immediately to avoid further damage.

Calibrate the Weighing System

Regularly calibrate the weighing system to ensure accurate material measurement, which is essential for producing high-quality concrete.

Self Loading Concrete Mixer Truck FAQs

How many cubic meters of concrete can a self loading concrete mixer truck load per batch?

The loading capacity varies by model, generally ranging from 2 to 12 cubic meters. For example:

- Small models: 2–4 m³

- Medium models: 4–6 m³

- Large models: 8–12 m³

Users can choose the suitable model based on the project size.

What is the total weight of a 6m³ self loading concrete mixer truck?

The total weight of the 6m³ model is about 12–14 tons (the exact weight varies depending on configuration, engine, and additional attachments).

What is the maximum transportation distance for concrete?

Self loading concrete mixer trucks are designed for short-to-medium distance transport, generally recommended within 50–100 km. For longer distances, it is advisable to use large transit mixer trucks to maintain concrete quality.

What is the drum rotation angle of a Self Loading Mixer Truck?

Most models provide a drum rotation angle of 270°–360°, making it convenient for mixing, discharging, and maneuvering, thereby improving construction efficiency.

Can a Self Loading Concrete Mixer Truck climb slopes or handle rough terrain?

Self loading concrete mixer trucks are equipped with high-torque engines and four-wheel drive or all-terrain tires (depending on the model), enabling safe travel on mild to moderate slopes and uneven ground. Typical performance features include:

- Climbing ability: usually capable of handling slopes of 20°–30°, and some 4WD models can achieve even higher grades.

- Rough terrain capability: equipped with reinforced tires and suspension systems, suitable for gravel roads, muddy construction sites, and light off-road environments.

Note: On extremely steep slopes or very soft ground, it is recommended to reinforce the surface or choose a specialized all-terrain model to ensure safety and maintain concrete quality.

Why Choose Haomei Machinery Self Loading Concrete Mixer Truck

As a professional manufacturer of self loading concrete mixer trucks, Haomei Machinery is committed to providing global customers with efficient, reliable, and versatile concrete construction solutions. Reasons to choose us include:

- Proven technology & rich experience: With many years of R&D and manufacturing experience, our products have been exported to 150+ countries and regions, tested in various complex construction environments.

- Multi-function & high efficiency: Our self loading mixer trucks integrate loading, mixing, transportation, and discharging into one machine. Easy to operate, significantly improving construction efficiency and reducing labor costs.

- Strong performance & all-terrain capability: High-torque engines, wear-resistant tires, and advanced suspension systems ensure stable and reliable performance on slopes, gravel roads, and complex jobsite conditions.

- Precise mixing & stable quality: Drum design and an automatic weighing system ensure accurate and uniform concrete batching, reducing waste and ensuring consistent quality.

Choosing Haomei Machinery means choosing high quality, high efficiency, and a globally trusted concrete machinery partner.