JS750 is a very common and classic forced twin-shaft concrete mixer, widely used in small and medium-sized construction projects, precast component factories, roads, bridges, hydropower, and other engineering works.

The JS750 concrete mixer represents a medium-sized twin-shaft forced mixer in the construction engineering field, widely used in commercial concrete batching plants, medium-sized construction projects (such as residential buildings, bridges, and road construction), and precast component factories.

JS750 Concrete Mixer Specifications

| Specification | Unit | Value |

| Discharging Volume | L | 750 |

| Charging Volume | L | 1200 |

| Mixer Capacity | m3 | 0.75 |

| Lubrication System | Brand | Choosed |

| Reducer | Brand | Choosed |

| Aggregate Size | mm | 60/80 |

| Aggregate Compartments | Quantity | 4 |

| Working Circle | S | 60S |

| Mixer Motor Power | KW | 30 |

| Mixing Speed | r/min | 30.5 |

| Mixing Blade | Quantity | 2x8 |

| Lifting Motor Power | KW | 7.5 |

| Pump Motor Power | KW | 1.1 |

| Weight | KG | 6150 |

| Dimensions | mm | 4550x2250x2450 |

JS750 Concrete Mixer Capacity

The JS750 concrete mixer has a discharge capacity of 750 liters, which is the final volume of concrete after a single mixing cycle. Its feeding capacity is 1200 liters, representing the total amount of raw materials loaded into the mixer. This capacity is suitable for producing approximately 35 cubic meters of concrete per hour.

- Discharge Capacity: 750 liters (final concrete volume per mix)

- Feeding Capacity: 1200 liters (total raw material volume)

- Productivity: approximately 35 m³/h

JS750 Concrete Mixer Features

- Forced Mixing: Unlike gravity mixers (such as the JZC series), the JS750 uses mixing blades on two counter-rotating shafts to perform forced shearing, pressing, and turning of the materials. This mixing method is highly efficient and ensures good uniformity, making it especially suitable for dry-hard concrete, lightweight concrete, and various other types of concrete.

- High Production Efficiency: Theoretical productivity ranges from 35-45 m³/h (depending on specific conditions and operation).

- Compact Structure: Compared to main mixers of the same capacity, it has a more compact design and occupies less space.

- High Reliability: Equipped with mature gear or cycloidal pin-wheel reducer transmission, it operates smoothly and has good durability.

- Can Operate Independently or as a Batching Plant Core: It can be used as a standalone machine in combination with a batching machine to form a simple plant or as the core main mixer for HZS35, HZS40, and other models of concrete batching plants.

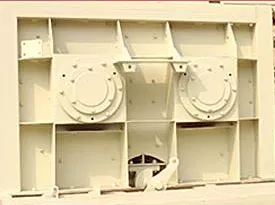

JS750 Concrete Mixer Main Components

| Component | Image | Description |

| Mixing System – Liners |

|

The JS750 concrete mixer uses thick, high-wear-resistant alloy cast iron liners manufactured with advanced production line technology. These liners provide excellent abrasion and impact resistance. Due to different contact conditions with aggregates, wear may be uneven. Liners are designed to be interchangeable to extend service life and maintain stable mixing efficiency. |

| Feeding System |

|

During operation, the material to be mixed is loaded into the hopper. The feeding system lifts the hopper via wire rope to the designated height. Once the hopper reaches the feeding rack, the gate automatically opens, allowing material to flow into the mixing drum through the chute. This ensures efficient, automated material input and reduces manual labor. |

| Discharge System |

|

The discharge gate is installed at the bottom of the mixer and operates automatically via pneumatic or hydraulic cylinders. Limit switches on both sides above the gate control its opening and closing. Adjustable sealing strips ensure a tight seal, prevent leakage, and guarantee smooth material output. |

| Lubrication Pump |

|

The lubrication pump quickly delivers oil to the shaft heads and includes a grease filter to prevent impurities from affecting sealing. This system improves equipment precision, reduces wear, and extends the service life of key components, supporting long-term reliable operation. |

| Water Supply System |

|

During operation, an electric motor drives a two-stage reducer, which powers two horizontal mixing shafts through open gears. The shafts rotate in opposite directions at equal speeds to ensure uniform, high-efficiency mixing. The integrated water supply system allows precise water addition to optimize concrete consistency and quality. |

JS750 Concrete Mixer Supporting Equipment

To form a complete production system, the JS750 is usually used in conjunction with the following equipment:

- PLD Series Batching Machines: such as PLD1200 or PLD1600, for automatic measurement of sand and stone aggregates.

- Cement Silos: typically equipped with an 80-ton or 100-ton silo for storing cement and fly ash.

- Screw Conveyor: used to transport cement from the silo bottom to the mixer.

- Control System: can be equipped with fully automatic or semi-automatic consoles for one-touch operation and precise measurement.

JS750 Concrete Mixer Applications

- Small and Medium-Sized Construction Projects: such as rural self-built houses, residential communities, factory construction, etc.

- Precast Component Factories: for producing cement piles, cement bricks, curbstones, etc.

- Road and Bridge Construction: used for small projects or as auxiliary equipment for large projects.

- Hydraulic Engineering: small and medium-sized dams, channels, etc.

- Commercial Concrete Batching Plants (HZS35/HZS50): As the core mixer of the batching plant, usually one JS750 combined with batching machine, cement silo, etc., forms an HZS50 batching plant (theoretical capacity 50 m³/h), meeting concrete supply needs for small and medium-sized urban construction and municipal projects.

- Medium-Sized Construction Sites: such as 10-20 story residential buildings, small bridges, factory roads; on-site mixer deployment reduces concrete transportation costs (avoiding slump loss from long-distance transport).

- Precast Component Factories: producing precast slabs, piles, inspection wells, etc., requiring stable and batch concrete supply. The JS750’s capacity and mixing uniformity can meet these demands.

JS750 Concrete Mixer Working Process

- Loading: The loader or batching machine dumps sand, stone, cement, and other aggregates into the lift hopper (or conveys them via a belt conveyor).

- Lifting: The hoist pulls the lift hopper along the track, pouring aggregates into the mixing drum.

- Water Addition: The pump or water tank injects a preset amount of water into the mixing drum.

- Mixing: The mixing motor starts, driving the two shafts to rotate in opposite directions, with blades thoroughly mixing the concrete mixture.

- Discharge: After mixing (usually 45-60 seconds), the cylinder or manual operation opens the discharge gate, allowing uniformly mixed concrete to flow into transport vehicles or hoppers.

JS750 Concrete Mixer Selection Recommendations

- Capacity Matching: If the daily concrete demand ≤500 m³, JS750 is a cost-effective choice; if demand exceeds 800 m³/day, a larger model (such as JS1000, theoretical capacity 100 m³/h) is recommended.

- Material Adaptation: If "special concrete" (such as self-compacting concrete, lightweight aggregate concrete) is required, confirm whether the manufacturer can customize blade structure (e.g., add shearing blades) and adjust mixing time.

- Installation Conditions: Plan the foundation in advance (concrete foundation thickness ≥300 mm, embedded bolts), power supply (requires 380V industrial power, total power approximately 50 kW), and raw material storage area (sand, stone stockpiles near feeding system to reduce transport costs).

- After-Sales Guarantee: Prefer manufacturers providing "rapid supply of consumable parts (liners, blades, sealing strips)" and "on-site maintenance" to avoid work stoppages due to parts shortages.

JS750 Concrete Mixer Common Faults and Troubleshooting

| Common Fault | Possible Cause | Troubleshooting |

| Uneven Mixing | Severe blade wear | Replace blades |

| Material ratio imbalance | Calibrate batching system | |

| Insufficient mixing time | Extend mixing time | |

| Discharge Gate Leakage | Sealing strip aging | Replace sealing strip |

| Discharge gate deformation | Correct gate deformation | |

| Insufficient hydraulic/pneumatic system pressure | Check hydraulic pump/pneumatic pump | |

| Motor Overload (Tripping) | Overfeeding | Reduce feeding amount |

| Hard objects stuck in the drum | Stop and remove hard objects | |

| Motor bearing damage | Replace motor bearings | |

| Lift Hopper Jam | Guide rail deformation | Correct guide rails |

| Chain loose/broken | Adjust chain tension/replace chain | |

| Aggregates blocking hopper | Clear hopper |

The JS750 concrete mixer is a "balance of capacity and cost-effectiveness" medium-sized equipment. Selection should consider project scale, raw material characteristics, and automation needs. During operation, strictly follow operating procedures and perform regular maintenance to ensure long-term stable operation.

The JS750 concrete mixer is a stable, moderately efficient, and flexible small to medium-sized concrete production machine, making it an economical and practical choice for many projects and commercial concrete plants.

Haomei JS750 Concrete Mixer Customer Cases

-

JS750 Mixer-Integrated HZS35 Concrete Batching Plant Operated in Saudi Arabia

JS750 Mixer-Integrated HZS35 Concrete Batching Plant Operated in Saudi Arabia

-

HZS35 Concrete Plant Installed in Nepal Using JS750 Mixer

HZS35 Concrete Plant Installed in Nepal Using JS750 Mixer

-

JS750-Powered HZS35 Concrete Batching Plant Delivered to Peru

JS750-Powered HZS35 Concrete Batching Plant Delivered to Peru