The HZS25 Concrete Batching Plant is a small-scale concrete production equipment with a theoretical productivity of 25m³/h. Its core configuration includes a JS500 twin-shaft compulsory mixer, a PLD series batching machine, and an electronic weighing system. The aggregate weighing accuracy reaches ±2%, while the powder weighing accuracy is ±1%. This equipment is suitable for small and medium-sized construction projects, precast factories, and similar applications.

The HZS25 Concrete Batching Plant is an economical and practical model that perfectly balances production capacity, investment cost, and operational flexibility. If you are looking for a reliable concrete solution for a small or medium-sized project with limited budget or requiring on-site mobility, the HZS25 is a highly recommended option.

Note: The details, materials, and control systems of the HZS25 may vary depending on the manufacturer, so it is important to carefully evaluate and compare before purchasing. In addition, it is generally not suitable for use as a large commercial concrete batching plant, as its output cannot meet the high-intensity, large-scale requirements of commercial concrete supply. For higher productivity, consider models such as HZS35, HZS50, or HZS60.

Parameters of HZS25 Concrete Batching Plant

| Model | HZS25 | |

| Specification | Unit | Value |

| Productivity | m3/h | 25 |

| Capacity of Mixer | m3 | 0.5 |

| Mixer Power | kw | 18.5 |

| Discharge Height | m | 3.8(for customers choice) |

| Aggregate Bin | Quantity | 3 |

| Aggregate Bin Capacity | m3 | 0.8 |

| Max. Weighing Value of aggregate | kg | 500 |

| Max. Weighing Value of cement | kg | 300 |

| Max. Weighing Value of water | kg | 160 |

| Max. Weighing Value of additive | kg | 20 |

| Aggregate Measuring Accuracy | % | 2 |

| Water Measuring Accuracy | % | 1 |

| Cement Measuring Accuracy | % | 1 |

| Additive Measuring Accuracy | % | 1 |

| Cement Silo | _ | Optional |

| Cement Screw Conveyor | _ | Optional |

| Cement Silo Capicity | _ | Optional |

| Control Mode | _ | Auto/Semi control |

Advantages of HZS25 Concrete Batching Plant

- Low Investment Cost: Compared with large batching plants (such as HZS75, HZS120, etc.), the purchase and operating costs of HZS25 are much lower, making it an ideal choice for small and medium-sized projects.

- Small Footprint: Compact structure with low site requirements.

- Easy Operation and Maintenance: High degree of automation, requires fewer operators, and daily maintenance is relatively simple.

- Strong Flexibility: Modular design allows for quick installation and relocation, making it suitable for mobile construction.

- Stable Product Quality: Equipped with precise electronic weighing and compulsory mixing, ensuring concrete uniformity and quality.

Efficient Mixing and Accurate Proportioning

The twin-shaft mixer adopts wear-resistant alloy liners and blades, ensuring good mixing uniformity, low noise, and long service life. The electronic weighing system supports automatic drop compensation and can store multiple mix ratios to meet the requirements of different concrete types.

Intelligent Control and Convenient Operation

The microcomputer control system supports internet monitoring and remote operation, allowing real-time adjustment of parameters (such as water setting value and batching volume) and automatic printing of production reports. The control interface features Chinese labels and a process-oriented button layout to reduce operational difficulty.

Modular Design and Quick Relocation

The structure is simple and easy to disassemble. Modular components make transportation and installation convenient, suitable for projects that require frequent relocation. Some models do not require complex foundations and can be installed on leveled ground.

Low Maintenance Cost

Key components (such as mixer liners and belt conveyors) are made of durable materials, and daily maintenance only requires regular lubrication and inspection.

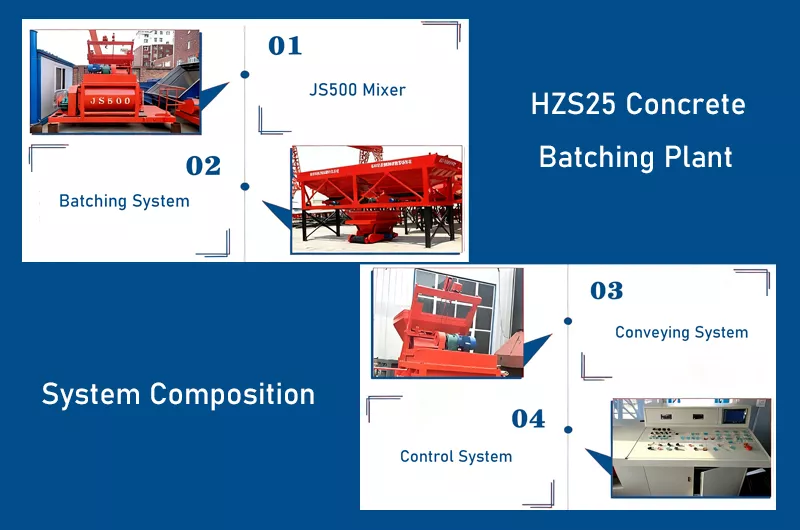

System Components of HZS25 Concrete Batching Plant

- Mixing System: Equipped with a JS500 twin-shaft compulsory mixer with high-chromium wear-resistant liners and blades, rated capacity of 500L, and motor power of 18.5kW. It supports mixing of various materials such as plastic concrete and dry hard concrete.

- Batching System: Configured with a PLD800/1200 concrete batching machine, with an aggregate bin capacity of 2.2–6m³, adopting a "pin"-type feeding structure and lever single-sensor weighing technology, with a batching capacity of 800–1200L.

- Conveying System: Includes two feeding options—belt conveyor (production capacity of 40T/h) or bucket elevator, and the screw conveyor has a maximum capacity of 3.8m³/h.

- Control System: Uses Schneider electronic components, supports automatic/manual dual-mode operation, equipped with a dynamic display panel and data storage function, enabling precise weighing of sand, cement, water, and additives.

Applications of HZS25 Concrete Batching Plant

- Small and Medium-Sized Construction Projects: Such as self-built houses in towns and villages, residential communities, office buildings, etc.

- Road and Bridge Construction: For on-site mixing in medium and small bridges, rural roads, and county road renovation projects.

- Water Conservancy Projects: Such as small reservoirs and canal linings.

- Precast Component Factories: For producing concrete blocks, curbstones, cement pipes, and other precast elements.

- Railway Construction: Used for branch lines or dedicated line construction.

- Environments with High Environmental Protection Requirements: Built-in dust removal and wastewater treatment systems make it suitable for urban or environmentally sensitive areas.

Popular HZS25 Concrete Batching Plant Models

- HZS25 Portable Electric Concrete Batching Plant

- HZS25 Mobile Batching Plant with Concrete Pump

- HZS25 Mini Concrete Mixer Batching Plant

- HZS25 Full‑automatic Mini Concrete Batching Plant (JS500)

- HZS25 Concrete Mixing Plant with Automatic Control System

Haomei HZS25 Concrete Batching Plant Customer Cases

-

HZS25 Concrete Mixing Plant in South Africa

HZS25 Concrete Mixing Plant in South Africa

-

Ethiopian HZS25 Concrete Batching Plant Equipped with JS500 Mixer

Ethiopian HZS25 Concrete Batching Plant Equipped with JS500 Mixer

-

HZS25 Concrete Batching Plant to Uzbekistan

HZS25 Concrete Batching Plant to Uzbekistan

-

Benin Customer HZS25 Concrete Batching Plant

Benin Customer HZS25 Concrete Batching Plant

-

HZS25 Concrete Batching Plant Kuala Baram

HZS25 Concrete Batching Plant Kuala Baram

-

YHZS25 Concrete Batching Plant in Nigeria

YHZS25 Concrete Batching Plant in Nigeria

-

YHZS25 Small Concrete Batching Plant in Indonesia

YHZS25 Small Concrete Batching Plant in Indonesia

-

YHZS25 Concrete Batching Plant in Vietnam

YHZS25 Concrete Batching Plant in Vietnam

-

YHZS25 concrete batching plant Saudi Arabia

YHZS25 concrete batching plant Saudi Arabia

-

Kenya HZS25 Concrete Batching Plant Equipped with JS500 Mixer

Kenya HZS25 Concrete Batching Plant Equipped with JS500 Mixer

-

HZS25 Concrete Batching Plant with JS500 Mixer Operating in Philippines

HZS25 Concrete Batching Plant with JS500 Mixer Operating in Philippines