The HZS150 Concrete Batching Plant is a large-scale concrete mixing equipment with a theoretical productivity of 150 cubic meters per hour, widely used in various construction projects. Its core component is the twin-shaft forced mixing main machine, which features high mixing quality and efficiency.

The HZS150 batching plant is typically employed by commercial concrete companies and in large-scale water conservancy, highway, bridge, and port construction projects. It is a key facility to ensure stable concrete supply and reliable quality.

Parameters of HZS150 Concrete Batching Plant

| Type | HZS150 |

| Productivity in theory | 150m³/h |

| Mixer | JS3000 |

| Total power | 205KW |

| Maximum aggregate diameter | 80mm |

| Aggregate feeding method | Conveyor belt |

| Aggregate bins volume | 4x18m³ |

| Aggregate weighing | 2x4000kg ±2% |

| Cement weighing | 1800kg ±1% |

| Fly-ash weighing | 800kg ±1% |

| Water weighing | 800kg ±1% |

| Additive weighing | 50kg ±1% |

| Discharging height | 3.8m |

| Overall dimension(during operating) (LXWXH) | 58.5mX7mX12.9m |

| Total weight | 77T |

| Control | Fully automatic central control |

| Cement silo(optional) | Required on clients' demand |

| Cement screw(optional) | Each cement silo equipped with one φ219 screw |

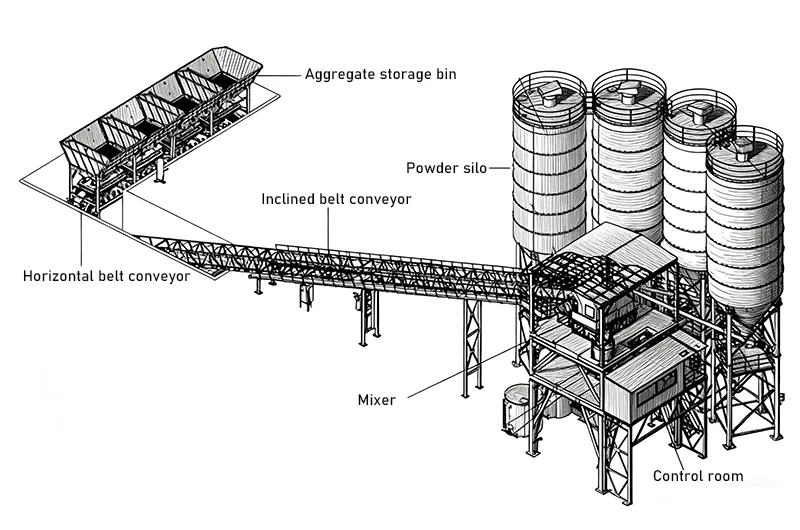

Components and Functions of HZS150 Concrete Batching Plant

A standard HZS150 batching plant mainly consists of the following systems:

Aggregate Supply System

- Aggregate Bins: Divided into multiple compartments to store sand, stone, and other aggregates separately.

- Aggregate Weighing Scale: Located below the batching machine, accurately measures the weight of each type of aggregate.

- Aggregate Conveyor Belt: Transports the weighed aggregates horizontally to the aggregate hopper above the mixing main machine. Commonly a flat belt conveyor.

Powder Material Supply System

- Cement Silo/Powder Silo: Used to store cement, fly ash, and other powder materials.

- Screw Conveyor: Transports powder materials from the bottom of the silo to the powder weighing scale.

- Powder Weighing Scale: Accurately measures cement, fly ash, and other powdered materials.

Liquid Supply System

- Water Tank: Stores water for mixing.

- Water Scale/Flow Meter: Accurately measures the weight or volume of water.

- Admixture Tank and Scale: Stores and measures various liquid admixtures.

Mixing System

JS3000 Mixing Main Machine: This is the core of the entire plant. The twin-shaft forced mixer can quickly and evenly mix dry, semi-dry, plastic, and various proportioned concretes, providing high mixing quality and efficiency.

Control System

- Control Room: The operator’s work center.

- Industrial Computer and PLC: Responsible for receiving mix designs, controlling various actuators (such as pneumatic gates, motors, etc.), collecting weighing data, and achieving fully automated production. Modern batching plants are usually equipped with remote monitoring and data management systems, allowing management to monitor production in real time.

Pneumatic and Dust Removal System

- Air Compressor: Provides power for pneumatic components.

- Dust Collector: Mainly installed on top of powder silos and above the mixing main machine to collect dust and protect the environment.

Workflow of HZS150 Concrete Batching Plant

- Batching: After the operator selects or inputs the production mix in the control room, the equipment is started. Each independent weighing system for aggregates, powders, water, and admixtures begins precise batching according to the set values.

- Feeding: The weighed aggregates are delivered to the temporary hopper above the mixer via the conveyor belt; powders, water, and admixtures are fed directly into the mixing main machine through their respective pipelines.

- Mixing: Once all materials enter the JS3000 main machine, forced mixing is performed. A complete mixing cycle (feeding, mixing, discharging) typically takes 60-90 seconds.

- Discharging: The freshly mixed concrete is discharged from the bottom of the main machine into waiting concrete mixer trucks.

- Cycle: After discharging, the system automatically proceeds to the next production cycle.

Features and Advantages of HZS150 Concrete Batching Plant

- High Efficiency: Theoretical output of 150 m³/h, capable of meeting the supply demands of large projects or commercial concrete plants.

- High Automation: Fully automatic control from batching to discharge, greatly reducing manual operation and improving production efficiency and management level.

- Accurate Measurement: Uses high-precision sensors and advanced control algorithms to ensure the accuracy of concrete mix ratios, guaranteeing project quality.

- High Reliability: Core components such as the mixing main machine, reducer, and electrical components use mature and reliable brands and designs to ensure long-term stable operation.

- Environmental Friendliness: Equipped with comprehensive dust removal and noise reduction devices, meeting modern environmental protection requirements.

- Modular Design: Compact structure, convenient installation, relocation, and transportation.

Applications of HZS150 Concrete Batching Plant

- Commercial concrete batching plants

- Large-scale water conservancy projects

- Highways and railway construction

- Ports, docks, and other large infrastructure projects

- Precast component factories

Construction Site Scenarios

In construction site scenarios, the HZS150 Concrete Batching Plant is mainly used for large-scale engineering projects, infrastructure construction, and high-rise building construction.

- High Equipment Stability: The HZS150 adopts a fixed design with a stable and reliable structure, capable of adapting to various complex construction environments. The modular design ensures good overall structural strength and stability, with low failure rate and maintenance cost during long-term use.

- High Automation: The batching plant uses a fully automated control system to achieve continuous and stable production operations, improving production efficiency. Operators can complete all operations from the control room, greatly reducing labor intensity.

- Strict Quality Control: The HZS150 is equipped with high-precision weighing systems, with aggregate weighing accuracy of ±2% and powder weighing accuracy of ±1%, ensuring accurate concrete mix ratios. The mixing main machine adopts a twin-shaft forced mixer, providing excellent mixing quality and homogeneous concrete.

Commercial Concrete Production Scenarios

- Multi-Variety Concrete Production: The HZS150 can produce concrete of various strength grades, from C15 to C60 and higher, meeting different project requirements. The batching plant is equipped with a separate admixture measurement system to meet the mixing requirements of high-strength concrete for different processes.

- Efficient Production Cycle: The mixing cycle of the HZS150 is 60 seconds, enabling high-efficiency continuous production. Advanced mixing mechanisms and core patented technology ensure dual-flow movement of materials, strong mixing, and high-efficiency blending, shortening mixing time and improving production efficiency.

- Complete Logistics and Delivery System: As a commercial concrete production plant, the HZS150 works closely with a fleet of concrete mixer trucks. The discharge height is 3.8–4.2 meters, suitable for various types of concrete transport vehicles.

Precast Component Manufacturing Scenarios

- High-Precision Batching Requirements: Precast components demand high homogeneity and strength in concrete. The HZS150’s high-precision weighing system meets this requirement. Cement, fly ash, water, and liquid admixtures are measured electronically to ensure consistent concrete quality.

- Automation Adaptability: Precast production lines usually have high automation. The HZS150’s automated control system can seamlessly integrate with the production line, ensuring timely and stable concrete supply.

- High Stability Requirements: The quality of precast components directly affects building safety, requiring extremely stable concrete quality. The HZS150 uses advanced mixing systems with short mixing time and excellent homogeneity, providing high-quality concrete for precast components.

The HZS150 Concrete Batching Plant is a mature, stable, and highly automated large-scale concrete production equipment, essential for modern industrialized and large-scale construction.

Supporting Equipment of HZS150 Concrete Batching Plant

The raw material supply equipment for the HZS150 Concrete Batching Plant mainly includes loaders and transport vehicles. Loaders are used for feeding sand and stone aggregates, usually 2–3 units depending on the scale of the aggregate yard and transport distance. Transport vehicles are mainly concrete mixer trucks, used to deliver mixed concrete to construction sites.

- The main function of the loader is to load sand and stone aggregates from the yard into the batching machine bins. Based on the HZS150’s production capacity, it is recommended to use loaders with bucket capacities of 3–5 m³ to ensure timely aggregate supply.

- The configuration of transport vehicles depends on the transport distance and concrete demand. Typically, each HZS150 batching plant requires 8–12 concrete mixer trucks to ensure continuous concrete supply.

Comparison Between HZS150 and Other Models of Concrete Batching Plants

The Haomei Machinery HZS series concrete batching plants are divided into multiple models according to theoretical hourly productivity, mainly including HZS25, HZS35, HZS50, HZS60, HZS75, HZS90, HZS120, HZS150, HZS180, HZS240, etc.

| Model | HZS25 | HZS35 | HZS50 | HZS60 | HZS75 | HZS90 | HZS120 | HZS150 | HZS180 | |

| Specification | Unit | Value | Value | Value | Value | Value | Value | Value | Value | Value |

| Productivity | m3/h | 25 | 35 | 50 | 60 | 75 | 90 | 120 | 150 | 180 |

| Capacity of Mixer | m3 | 0.5 | 0.75 | 1 | 1 | 1.5 | 1.5 | 2 | 3 | 3 |

| Mixer Power | kw | 18.5 | 18.5 | 37 | 37 | 44 | 44 | 74 | 110 | 110 |

| Discharge Height (for customers choice) | m | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 |

| Aggregate Bin | Quantity | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 |

| Aggregate Bin Capacity | m3 | 0.8 | 1.2 | 1.6 | 1.6 | 2.4 | 2.4 | 3.2 | 4.8 | 4.8 |

| Max. Weighing Value of aggregate | kg | 500 | 850 | 1000 | 1000 | 1300 | 1300 | 1500 | 1800 | 1800 |

| Max. Weighing Value of cement | kg | 300 | 500 | 800 | 800 | 1100 | 1100 | 1100 | 800 | 800 |

| Max. Weighing Value of water | kg | 160 | 300 | 350 | 350 | 500 | 500 | 1500 | 800 | 800 |

| Max. Weighing Value of additive | kg | 20 | 30 | 30 | 30 | 40 | 40 | 60 | 50 | 50 |

| Aggregate Measuring Accuracy | % | 2 | 2 | 2 | 2 | 2 | ±2% | ±2% | ±2% | ±2% |

| Water Measuring Accuracy | % | 1 | 1 | 1 | 1 | 1 | ±1% | ±1% | ±1% | ±1% |

| Cement Measuring Accuracy | % | 1 | 1 | 1 | 1 | 1 | ±1% | ±1% | ±1% | ±1% |

| Additive Measuring Accuracy | % | 1 | 1 | 1 | 1 | 1 | ±1% | ±1% | ±1% | ±1% |

| Cement Silo | Optional | Optional | Optional | Optional | Optional | Optional | Optional | Optional | Optional | |

| Cement Screw Conveyor | Optional | Optional | Optional | Optional | Optional | Optional | Optional | Optional | Optional | |

| Cement Silo Capicity | Optional | Optional | Optional | Optional | Optional | Optional | Optional | Optional | Optional | |

| Control Mode | Auto/Semi control | Auto/Semi control | Auto/Semi control | Auto/Semi control | Auto/Semi control | Auto/Semi control | Auto/Semi control | Auto/Semi control | Auto/Semi control |

As the model size increases, the technical parameters of the batching plant are correspondingly enhanced. The HZS150, at the 150 m³/h production level, shows significant improvements compared to the HZS120, and compared to the HZS180, it has a similar configuration of the mixing main machine and batching machine, but with slightly lower production capacity.

Concrete Batching Plant Selection Recommendations

Selection recommendations for different needs

Small-scale projects (daily demand < 500 m³):

- Recommended Models: HZS35, HZS50, HZS60

- Reason for Selection: Lower equipment investment, smaller footprint, simple installation and commissioning, low operating costs

- Notes: If the project duration is long or there is potential for production expansion, HZS60 can be considered to reserve capacity for future development

Medium-scale projects (daily demand 500–1000 m³):

- Recommended Models: HZS90, HZS120, HZS150

- Reason for Selection: Moderate production capacity, high cost-performance ratio, wide applicability

- Notes: Although HZS150 has higher investment, its large production capacity makes it more economical for long-term use

Large-scale projects (daily demand > 1000 m³):

- Recommended Models: HZS180, HZS240, or dual-main machine configuration

- Reason for Selection: High production capacity, capable of meeting large-scale continuous construction demands

- Notes: If site space is limited or project schedule is tight, a dual-main HZS150 configuration can be considered for greater flexibility

Commercial Concrete Production:

- Recommended Models: HZS120, HZS150, HZS180

- Reason for Selection: Strong production capacity, stable product quality, flexible mix design management

- Notes: Consider transport radius and market demand to determine production capacity reasonably

Precast Component Manufacturing:

- Recommended Models: HZS90, HZS120, HZS150

- Reason for Selection: High weighing accuracy, excellent mixing quality, high automation

- Notes: Pay special attention to batching accuracy and mixing uniformity, and consider high-configuration versions

As a high-end product among medium-sized batching plants, the HZS150 has significant advantages in technical performance, production capacity, and applicability. It can meet the demands of various large-scale construction projects and is also suitable for commercial concrete production and precast component manufacturing.

Compared with other models, the HZS150 demonstrates good cost-performance ratio and adaptability. Although its investment is relatively high, its large production capacity, mature technology, and high reliability make it economically advantageous for long-term use. Especially at the 150 m³/h production level, the HZS150 shows a clear competitive edge.

When making a selection, users should consider their actual needs and comprehensively evaluate production scale, site conditions, investment budget, and technical requirements to choose the most suitable model. For most medium-sized projects and commercial concrete production companies, the HZS150 is an ideal choice. It meets production requirements while providing good economy and reliability, making it an important equipment for modernizing concrete production.

Haomei HZS150 Concrete Batching Plant Customer Cases

-

Saudi Arabia HZS150 Concrete Batching Plant Successful Commissioning Case

Saudi Arabia HZS150 Concrete Batching Plant Successful Commissioning Case

-

Pakistan HZS150 Concrete Batching Plant Installation Site Showcase

Pakistan HZS150 Concrete Batching Plant Installation Site Showcase

-

Bangladesh HZS150 Concrete Batching Plant Project Installation On-Site Photos

Bangladesh HZS150 Concrete Batching Plant Project Installation On-Site Photos

-

Indonesia HZS150 Concrete Batching Plant Completion Case Sharing

Indonesia HZS150 Concrete Batching Plant Completion Case Sharing