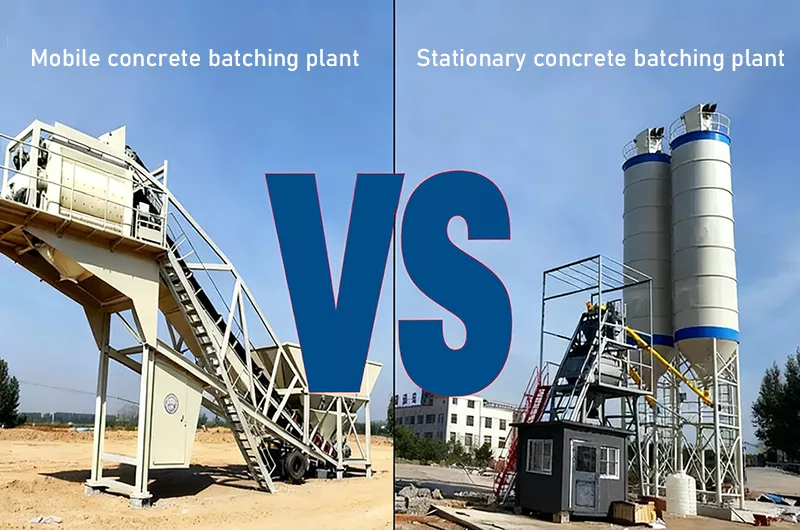

To determine whether a stationary concrete batching plant or a mobile concrete batching plant is more suitable for a project, the core is to match the equipment features with the project requirements — the two types differ significantly in terms of capacity, flexibility, site requirements, cost, and applicable scenarios.

Stationary vs. Mobile Concrete Batching Plants

| Feature Dimension | Stationary Concrete Batching Plant | Mobile Concrete Batching Plant |

| Mobility & Installation | Permanently installed, complex foundation work, installation and dismantling are time-consuming and costly. | Modular design, can be transported as a whole or quickly relocated. Installation and dismantling are fast, usually completed within a few days. |

| Production Capacity | High: typically designed for large-scale, highly efficient production. Output ranges from tens to hundreds of cubic meters per hour, easily meeting large-scale demands. | Medium to low: limited by mobility, usually smaller in scale and output. Common output ranges from 30-120 cubic meters per hour. |

| Investment Cost | Expensive equipment, plus substantial investment in land, foundation, and supporting facilities (e.g., silos, office buildings). | Initial equipment investment is relatively low, saving significant costs in foundation and infrastructure. |

| Applicable Project Types | Long-term, large, centralized projects: | Short-term, dispersed, mobile projects: |

| Large-scale hydraulic engineering (e.g., dams) | Road and railway construction projects (moving with project progress) | |

| Large bridges, ports | Medium and small hydraulic projects | |

| Commercial concrete companies | Multiple dispersed construction sites | |

| Long-term large real estate development projects | Military projects, disaster recovery, and other emergency projects | |

| Automation & Environmental Protection | Excellent: easy to achieve high-level automation, dust and noise control facilities can be more complete and effective. | Good: automation and environmental protection levels are improving, but usually not as comprehensive as stationary plants due to mobility limitations. |

| Site Requirements | High: requires large, flat, permanent or long-term site, with specific geological conditions. | Low: low site requirements, just a relatively flat area for quick deployment. |

| Long-term Operating Cost | Low (at full load): due to high efficiency and automation, the cost per cubic meter of concrete is more advantageous for large-scale production. | Higher: cost per cubic meter may be higher than efficiently operating stationary plants, but saves on transportation and time costs. |

How to Choose Between Mobile and Stationary Concrete Batching Plants?

Both stationary and mobile concrete batching plants have their applicable scenarios. Choosing the most suitable type for your project mainly depends on the specific requirements of the project, such as scale, duration, and location.

Stationary Batching Plant

Best for: large, long-term projects, such as highways, dams, or commercial development projects, as well as enterprises requiring high output and continuous production.

Advantages:

- High production capacity.

- Suitable for a single, long-term site.

- Can be equipped with advanced automation systems to improve efficiency.

Disadvantages:

- High upfront investment.

- Requires significant installation time and site preparation.

- Poor flexibility; relocation after installation is difficult and costly.

- If far from the construction site, transportation costs of concrete are higher.

Mobile Concrete Batching Plant

Best for: short-term projects, remote projects, or multiple projects at different locations, because they are easy to move.

Advantages:

- Highly flexible and portable, can be quickly installed and relocated.

- On-site concrete production, reducing transportation costs.

- Lower installation cost and time.

- Cost-effective for medium and small projects.

Disadvantages:

- Lower production capacity compared to stationary batching plants.

- Unit price may be higher than some stationary plants.

Selection Recommendations

- Stationary batching plants are more suitable for large, long-term projects that require continuous, high-volume concrete production.

- Mobile batching plants are more suitable for short-term, dispersed projects that require flexibility and frequent relocation.

| Evaluation Factors | Selection Criteria | Recommended Type |

| Project Scale & Duration | Large, long-term projects (e.g., urban infrastructure) | Stationary Concrete Batching Plant |

| Project Scale & Duration | Medium and small, short-term or dispersed projects | Mobile Concrete Batching Plant |

| Site Conditions | Fixed site, ample space | Stationary Concrete Batching Plant |

| Site Conditions | Limited site or frequent relocation required | Mobile Concrete Batching Plant |

| Cost Budget | Sufficient budget and pursuit of long-term benefits | Stationary Concrete Batching Plant |

| Cost Budget | Control initial investment | Mobile Concrete Batching Plant |

- If the project is large in scale, long in duration, and the site is stable, stationary plants are preferable.

- If flexibility is needed to respond to short-term, dispersed, or complex site requirements, mobile plants are a more economical and efficient choice.

6 Key Factors to Choose the Right Concrete Batching Plant

Project Scale and Total Concrete Demand: Core Judgment Criterion

Choose stationary: for large projects with high total demand, suitable for projects with a total concrete demand ≥ 10,000 m³, such as:

- Large-scale infrastructure: high-speed rail, highways, bridges, hydropower stations, large factories.

- Real estate: residential communities with multiple buildings (≥10 buildings), commercial complexes.

- Industrial projects: foundations for large chemical equipment, heavy-duty factory floors.

Reason: Stationary plants with high capacity can quickly meet demand, avoiding "equipment at full load still cannot meet the schedule," and long-term operation has low unit cost, reducing total project cost.

Choose mobile: for small to medium projects with low total demand, suitable for projects with a total concrete demand ≤ 5,000 m³, such as:

- Small-scale infrastructure: rural roads, township bridges, small hydraulic projects.

- Residential construction: self-built houses in rural areas, detached/townhouse villas in urban areas, renovation of old buildings.

- Temporary projects: temporary site construction, emergency repairs (e.g., road patching).

Reason: No need to invest heavily in a stationary plant, avoiding the waste of "large equipment doing small work."

Project Duration and Site Usage Period: Short-term temporary projects choose mobile, long-term stable projects choose stationary

- Choose stationary: duration ≥ 6 months, site can be used long-term. If the project lasts 2-3 years and the site is exclusive to the project (or can be leased long-term), the "high investment + low long-term cost" advantage of stationary plants gradually emerges — initial foundation costs can be spread over long-term production, and the equipment stability is more suitable for long-term continuous operation.

- Choose mobile: duration ≤ 3 months, temporary site lease. If the project is short (1-2 months) or the site is temporarily occupied (e.g., municipal temporary land use), mobile plants require no foundation, and their quick installation and dismantling prevent the problem of "project ends, stationary plant has not recovered costs," and no construction waste is left after relocation.

Site Conditions: Fixed and sufficient space are hard constraints

Choose stationary: fixed site with sufficient area, meeting two conditions:

- Site ownership/lease period matches the project duration

- Flat site, can accommodate silos (sand and aggregate storage), main batching machine, control room, vehicle access (usually reserve 10-15m wide passage). Note: some cities have environmental restrictions on stationary plant locations (e.g., far from residential areas and water sources), planning permission must be obtained in advance.

Choose mobile: limited/dispersed site, or no fixed site

Suitable scenarios:

- Small urban projects (e.g., road renovation within a residential community) where space is too narrow for a stationary plant.

- Multiple dispersed sites (e.g., 3-5 rural self-built houses in the same area), mobile equipment can work in rotation without repeated station construction.

Concrete Transport Radius and Cost: Closer to site is more cost-effective

Concrete transport has a "golden radius" (usually ≤15km). Beyond this, segregation and initial setting occur easily, and transport costs soar:

- Choose stationary: centralized sites within transport radius. If all construction points are around the stationary plant (e.g., large residential complex buildings), with transport distance ≤10km, the high capacity of stationary plants matches transport efficiency, lowering total cost.

- Choose mobile: remote/dispersed sites, transport radius > 15km. For mountain road renovations or remote rural housing, transporting from a city stationary plant is costly and quality is hard to guarantee. Placing a mobile plant directly at the site ("zero-distance supply") greatly reduces transport cost and ensures fresh concrete.

Concrete Mix Ratio Requirements: Single mix choose stationary, multiple mixes choose flexible

- Choose stationary: single or stable mix. If the project only requires 1-2 types of concrete, the stationary batching system (accuracy ±1%) is more stable, with smaller batch-to-batch variation and better quality control.

- Choose mobile: frequent mix changes. If multiple mix types are required, mobile equipment provides more flexible mix adjustment, suitable for small-batch, multi-variety production.

Environmental and Policy Requirements: High requirements choose stationary, temporary projects choose mobile

Current environmental policies are becoming stricter, especially in urban and surrounding areas:

- Choose stationary: long-term compliance with environmental standards. If the project is in an environmentally sensitive area (e.g., urban built-up areas, scenic spots), stationary plants can be equipped with fully enclosed silos, pulse dust collectors, wastewater recycling systems, easily passing environmental inspections, suitable for long-term operation.

- Choose mobile: short-term, temporary, lower environmental requirements. If the project is in remote areas (e.g., rural), environmental inspections are more lenient, and mobile plants with basic dust removal (e.g., bag filters) meet basic standards. After the project, the plant can be quickly relocated without long-term environmental maintenance costs.