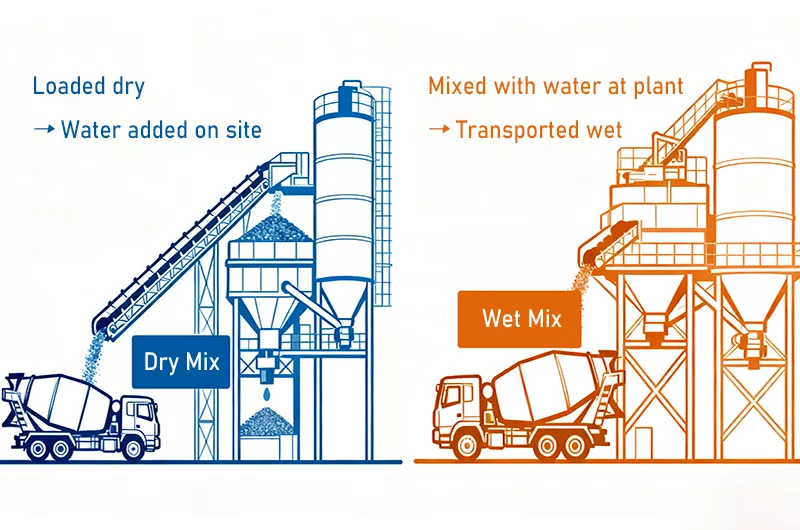

The difference between "dry mix" and "wet mix" in a concrete batching plant essentially lies in where the water is added, which results in process variations from production, transportation to construction.

Dry mix refers to loading only dry materials (cement, sand, and gravel) into the mixer truck, and then adding water at the construction site or during transportation. Wet mix, on the other hand, involves thoroughly mixing all raw materials (including water) at the batching plant before transporting the ready-mixed concrete to the construction site.

| Comparison Items | Dry Batching | Wet Batching |

| Core Definition | Aggregates, cement, fly ash, and other dry materials are proportioned and mixed at the batching plant without adding water or with only a small amount of water, and then transported to the site. | All materials (including water) are completely and uniformly mixed at the batching plant before the finished concrete is transported to the site. |

| Water Adding Location | Water is added and mixed inside the mixer truck during transportation or at the construction site. | Water is added and mixed at the batching plant before leaving the factory. |

| Transport Condition | The transported material is a dry mix. The truck drum rotates slowly to keep materials mixed and prevent segregation. | The transported material is fluid ready-mixed concrete. The truck drum keeps rotating to maintain the workability of the concrete. |

| Common Names | Dry mix, dry batched material | Ready-mix concrete, commercial concrete |

| Mixing Equipment | Batching plant + on-site mixing equipment (such as mixer truck or compulsory mixer) | Central mixer at the batching plant + mixer truck (for maintaining moisture during transit) |

| Quality Control | Conducted on-site, depending on the accuracy of water addition and mixing uniformity. More difficult to control quality. | Conducted at the batching plant with a strict quality control system. Stable and uniform quality. |

| Advantages | Long transport distance: dry materials are less likely to deteriorate, suitable for long-distance transportation. | Stable quality: industrial production with precise proportioning and uniform mixing. |

| High flexibility: water and admixture dosage can be adjusted based on site conditions. | High construction efficiency: ready to pour upon arrival, saving on-site mixing time. | |

| No waste: no residual concrete, and mixer trucks don’t need daily washing. | Environmentally friendly: centralized production reduces dust and noise pollution. | |

| Better workability: concrete consistency and slump are easier to control. | ||

| Disadvantages | Quality fluctuation risk: improper water addition on-site can seriously affect concrete strength. | Transport time limitation: must be poured and vibrated before the initial setting of concrete. |

| Environmental issue: on-site mixing generates dust and noise. | Requires precise scheduling: accurate coordination among batching plant, transport, and construction site. | |

| Requires on-site space: additional area and equipment for mixing are needed. | Short transport distance: typically within 1.5 hours of travel. | |

| Generates waste: daily truck washing produces wastewater and residue. | ||

| Typical Applications | Projects in remote areas far from cities. | Most urban construction projects (buildings, bridges, roads, etc.). |

| Small-scale, scattered repair or maintenance works. | Large-scale, centralized construction projects. | |

| Projects requiring special on-site adjustments (e.g., use of special additives). | Projects with high concrete quality requirements and stable supply needs. | |

| Dry-mix mortar, special mortar, etc. |

Dry Mix Concrete Batching Plant

Dry-mix concrete is suitable for small projects, remote areas, or situations where on-site mixing is needed for quality control.

Wet-mix concrete, on the other hand, is ideal for large-scale, high-strength, and high-consistency projects.

Process: Aggregates (sand and stone), cement, and fly ash are accurately measured in the batching system at the plant, then loaded into the drum of the concrete mixer truck. During transport, the drum rotates slowly to ensure uniform mixing of dry materials without adding water. Upon arrival at the construction site, a precisely measured amount of water and admixtures is added—either from the truck’s built-in water tank or the site’s water supply system—and the drum mixes the contents until a uniform concrete is formed.

Advantages:

- Flexible transportation — ordinary trucks can be used, suitable for remote or scattered job sites.

- Long storage life — no “over-time setting” issue, materials can be used on demand.

- Ideal for small-volume use, avoiding “leftover waste” of wet mix.

Disadvantages:

- Requires precise water control on-site (too much water reduces strength, too little affects workability).

- Not suitable for large-scale continuous construction (low mixing efficiency affects progress).

- Mostly used for mortar or low-strength concrete, rarely for high-strength structural concrete.

Wet Mix Concrete Batching Plant

Process: This is the most common method in modern construction. All raw materials—including water and admixtures—are precisely measured and thoroughly mixed in the central mixer at the batching plant. The resulting concrete is a fully prepared, fluid mixture that meets required specifications. It is then loaded into mixer trucks, whose drums rotate slowly during transport to prevent segregation (separation of aggregates and slurry) and premature setting.

Advantages:

- Stable quality (factory-standardized production, accurate proportioning, and slump control).

- High construction efficiency — ready for direct pouring, ideal for large-scale continuous operations.

- Reduces on-site labor and equipment requirements, simplifying construction management.

Disadvantages:

- Transport limitations (requires special mixer trucks, transport radius usually ≤50 km; risk of setting if delayed).

- Requires precise construction scheduling (once trucks arrive, concrete must be used immediately to avoid waste).

- Higher transportation cost; uneconomical for small projects (high minimum truck charge and per-unit cost).

How to Choose a Concrete Batching Plant?

- For home renovation, repair, or small-scale mortar work: choose dry mix (flexible, cost-effective, reduces waste).

- For main structural construction such as buildings, bridges, or roads: choose wet mix (stable quality, high efficiency).

- For remote sites or long-distance transport: choose dry mix (wet mix may set during transport).

- For high-strength concrete requirements (C30 and above): choose wet mix (dry mix water variation can affect strength).

Wet-mix concrete is the preferred choice in modern construction, representing industrialization, standardization, and high quality. It ensures stable and uniform concrete performance, making it ideal for large projects with strict structural strength requirements.

Dry-mix concrete serves more as a complementary or special-purpose solution. It offers distinct advantages for long-distance transportation and is indispensable in scenarios where batching plants cannot be established or where the demand is highly scattered, such as remote road maintenance or small foundation treatments.